Salt Spray Test Chamber Manufacturer in India

Freedom from Corrosive Damage: With Salt Spray Test Chambers from TestChamberHub.com

In industries like automobiles, marine, aerospace, electronics etc. where the tools,equipment, components, parts and so on, which are made of metal face harsh environments and that is why you need to keep resistance to rusting as your number one priority if you work in these fields. This silent killer of salt spray can cause a lot of decomposition to the structure by rusting and pitting, which will diminish the performance and the protection of your product.

At TestChamberHub.com, We have the absolute solution to our advanced and superior quality Salt Spray Chambers which are specially crafted to artificially generate environment which are highly corrosive so that exposing your products in this environment you become aware of the potential failures which you can improve by assessing them and after that use coating and other forms of protections to your product.

With Our Salt Spray Test Chamber, You Will Be Able to:

● Artificially Create A Highly Corrosive Atmosphere: Precisely recreate the conditions of salt fog within our Chambers by maintaining the right measurement of salinity, temperature and humidity, artificially creating the real life Marine and industrial atmosphere.

● Speed up Corrosion Testing: Gain important information on rusting Pro properties of your products in a much diminished period of time which is not possible and the product is being exposed to the natural situations.

● Assess Effectiveness of Coatings: Examine how corrosion resistance the protective layers are with the help of these chambers. Your paints, electroplating and coatings etc. all can be tested for their effectiveness.

● Recognize Failure System: Identify the unique Areas where the corrosion is initiated and expanded, with the help of this it's easier to make specific improvement in selecting the right material and also fix the surfaces.

● Ensure Accordance with Quality Regulations: Perform your testing procedures into perfect compliance with ASTM B117, ISO 9227 other regulatory norms of salt spray testing.

Why must you choose testchamberhub.com for your salt spray testing requirements?

At TestChamberHub, we know that resistance to corrosion is an important thing which hankers the functionality of various types of products. We provide not just the best quality equipment but we offer a detailed and specific solution to your corrosion testing problems:

● Accurate and Homogenous Salt Fog Scattering: Our Chambers are manufactured to provide continuous and uniform salt fog exposure within the whole area where the testing is conducted which alternately gives you trustable and repeatable results.

● Versatile Chamber Range: We provide a wide variety of Chamber in different sizes and configurations which are suitable for various specimens and testing volumes.

● Hi-tech Data Tracking and Control mechanisms: Observe the important test calculations in real time and precisely maintain and control the corrosive area and do significant changes in your products with the help of the acquired knowledge.

● Easy to Use Operation and maintenance: Our Chambers are manufactured by keeping convenience, ease in operation and low maintenance, in our minds ensuring effective and trustable testing procedures.

● Support of the Expert Team: our highly skilled professionals are available to guide you in picking the most appropriate chamber and also help in developing the highly efficient salt spray testing norms which fit the in quality standards for your specific products.

Do not let your product's quality and shelf life be ruined completely by silent corrosion. Proactively examine and increase their ability to resist corrosion with the help of our salt spray test Chambers which are known for providing accurate and reliable outcomes.

Safeguard against Trusted Find out Our Chambers Solutions

● Explore our wide range of salt greater Chambers which are meticulously manufactured for a wide variety of applications. These equipment come in many shapes and sizes and also consist of the unique characteristics and you

can take the one which fits the best for you.

● Request for a quote and make us aware about your specific corrosion testing related issues and needs.

● Talk with us. Our team of experts is here to give you the best advice on how to pick the salt spray chamber which will help you in resolving all the problems you're facing in this aspect and help you achieve great heights in your business.

Make sure that your metallic elements stay durable and reliable for a long period of time. Purchase our advanced hi-tech and trustable salt test spray Chambers and keep rusting corrosion in check.

Technical Parameters

|

Model |

Corrox - 108 |

|

Inner Box Size (L*W*H) |

60*45*40 cm (Can be customized) |

|

Outside Box Size(L*W*H) |

107*60*118 cm (Can be customized) |

|

Equipment Material |

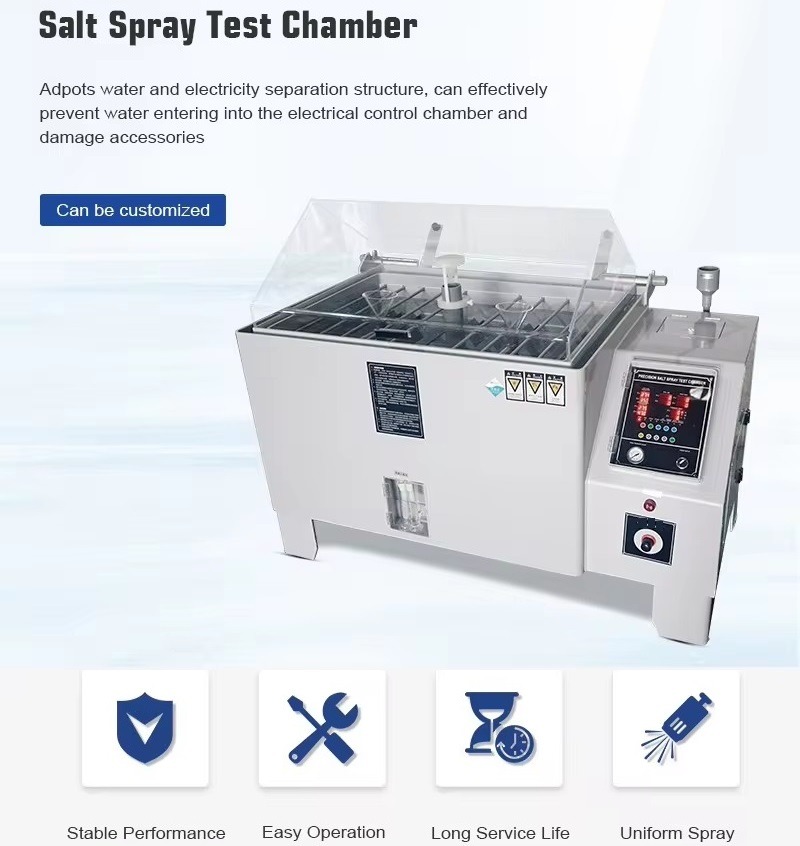

Both inside & outside shell adopt imported PP rigid Polymer, and tank cover uses imported transparent P.V.C. rigid plastic board |

|

Temperature Range |

Ambient+5°C~55°C |

|

Temperature Fluctuations |

≤±0.5°C |

|

Temperature Uniformity |

≤±2°C |

|

Temperature Precision |

±1°C |

|

Test Chamber Temperature |

Salt Spray Method (NSS ACSS)35±1°C |

|

Saturated air Barrel Temperature |

Salt Spray Method (NSS ACSS)47±1°C |

|

Brine Tank Temperature |

35°C±1°C |

|

Spray Quantity |

1.0~2.0 ml / 80cm2 / hr |

|

PH |

Salt Spray Method (NSS ACSS6.5~7.2) |

|

Lab Volume |

108L (Can be customized) |

|

Brine Tank Capacity |

Up to 300 L |

|

Power |

Single phase, AC220V,10A |

|

Multiple Safety Protection Devices |

Current discharge protection, Pressure Overshoot protection, temperature overshoot protection, over load fuse protection |

|

Accessories |

Testing Salt/ Measuring tank/ Equipment each 1 set |

|

Standards |

CNS: 3627, 3385, 4159, 7669, 8886; |

Air Compressor requirement: Approximately 7 cfm (Air Compressor is not inclusive with the machine) Main airline pressure regulator with filter is in customer scope.

|

MODEL |

Internal Size : (in mm) |

External Size : (in mm) |

|

Corrox - 250 |

800 X 500 X 550 |

1850 X 990 X 1190 |

|

Corrox - 450 |

900 X 700 X 750 |

2050 X 1050 X 1550 |

|

Corrox - 600 |

1000 X 700 X 850 |

2150 X 1150 X 1750 |

|

Corrox - 1000 |

1600 X 700 X 800 |

2650 X 1170 X 1650 |